aircraft sheet metal drawing course

Critical Dimensions Sheet Metal Forming Outside dimension should be used unless the inside dimension is critical. Sheet metal inspection fabrication and repair ACRATS Sheetmetal Working Courses Part 145- Aircraft Metallic Structure Technician Beginner Level Basic Aircraft Metallic Skills Training.

Hudson 4 Sheet Metal Drawing Technical Drawing Drawing Projects

Aircraft Wood Tubular and Fabric Repair.

. Top Sheet Metal Courses Online - Updated January 2022 Udemy. This gives brass sheet a wider range of performance depending on end use of the designed part. Training is performed primarily on assemblies and panels workbenches and some actual aircraft components.

7 Sheet and plate metalwork 277 71 Sheet and plate metalwork introduction 278 72 Roll-bending sheet metal and plate 296 73 Flow forming sheet metal 301 74 The principles of metal spinning 318 75 Swaging sheet metal 324 76 Basic fabrication procedures 330 Exercises 345 8 Structural steelwork and pipework 347. EDRS PRICE MF-075 HC-150 PLUS POSTAGE. INSTITUTION Dade County Public Schools Miami Fla.

23032020 - 10042020 Tallinn Estonia. BLOCK IV - FABRICATION METHODS. We typically use C2680 for sheet metal forming.

Web Development Data Science Mobile Development Programming Languages Game Development Database Design Development Software Testing Software Engineering Software Development Tools No-Code Development. Monday through Thursday. This is hands on individual work part classroom part shop training.

View reduce_03 aircraft sheet metal basicpdf from ENG 381 at 21st Century Learning Academy Charter High. Upon completion of training the student will gain the skills and confidence needed to work in an aircraft maintenance environment in a structures team. Types of Drawings Schematics Sketches Charts and graphs.

Oklahoma aviation employers had drawn more aviation sheet metal mechanics from our Aviation Sheet Metal training program than any other since 2006. Describe good safety practices in aircraft sheet metal work. 25 Noon to 4 pm.

All of these aircraft sheet metal tools packaged at a savings only a Yardstore sheet metal tool kit can deliver. Set up safety program for metal shop. Course Introduction Types of drawings Engineering also known as production or working drawings.

Technical Mathematics for the AME. Sheet Metal for Aviation Industrial Centre Composites. Aircraft are built and wired per drawings and blueprints.

Sheet metal stampingdrawing car industry 90million cars and commercial vehicles produced worldwide in 2014. The student must be able to. Order Aircraft Systems Training.

Beginner Sheet Metal Worker training the student will develop basic practical skills and understanding of sheet metal structure fabrication and repair. Number of Courses Available. This second portion of the class focuses on advanced aviation sheet metal skills.

Aircraft Drawing and Blueprint Reading. Demonstrate making parts from drawings original parts. Stamping Auto body panels 3 to 5 dies each Prototype dies 50000 Production dies 075-1 Forming dies Trimming station.

Our aircraft sheet metal tool kit packages include nearly all the aircraft sheet metal tools youll need including a rivet gun hole finders rivet sets buckings bars clecos clamps drills and much more. BRASS Low carbon steel contains 005-032 carbon compared to medium high and ultra-high carbon steel. 2 theory 1 exercises on aircraft Sheet metal repair Damage evaluation.

Principles and Applications of NDT. Todays aircraft technician relies on a wide variety of powered and hand-operated tools to precisely bend and. Aircraft Sheet Metal Multiple Sheetmetal Composites classes are run at once with overlapping schedules and as a result new classes often start every two months.

July 12 - Oct. Introducing Sheet Metal Design and Manufacturing Us ing CATIAV5 and CNC Equipment in an Aircraft Materials Course Abstract Students of the Aviation Department at Purdue University enroll in a computer graphic s course CGT 162 during their freshmen year and in this course they learn how to use the CATI A V5 Solid modeling software. Depending on the quantity of zinc in the alloy.

AMT Awarded FAA Approved. Upon completion of training the student will be able to assist experienced structures technicians in the aircraft line or base maintenance environment. During this training the student will develop basic practical skills and understanding of sheet metal structure fabrication and repair.

Aircraft Structures Workers mark and cut sheet metal according to engineering drawings. The course includes lecture demonstration and hands-on practice. An Authorized Course of Instruction for the Quinmester Program.

Learn how to navigate through the Structural Repair manual selecting and properly using the right tools learn and practice the safety aspects of sheetmetal work typical chemical handling use power shears and. During this training the student will advance hisher practical skills and understanding of sheet metal structure fabrication and repair according manufacturer documentation. All practical exer-.

Basic Aircraft Sheet Metal Introduction. Tuition is 528 per trainee. Sheet metal forming dates back to the days of the blacksmith who used a hammer and hot oven to mold metal into the desired form.

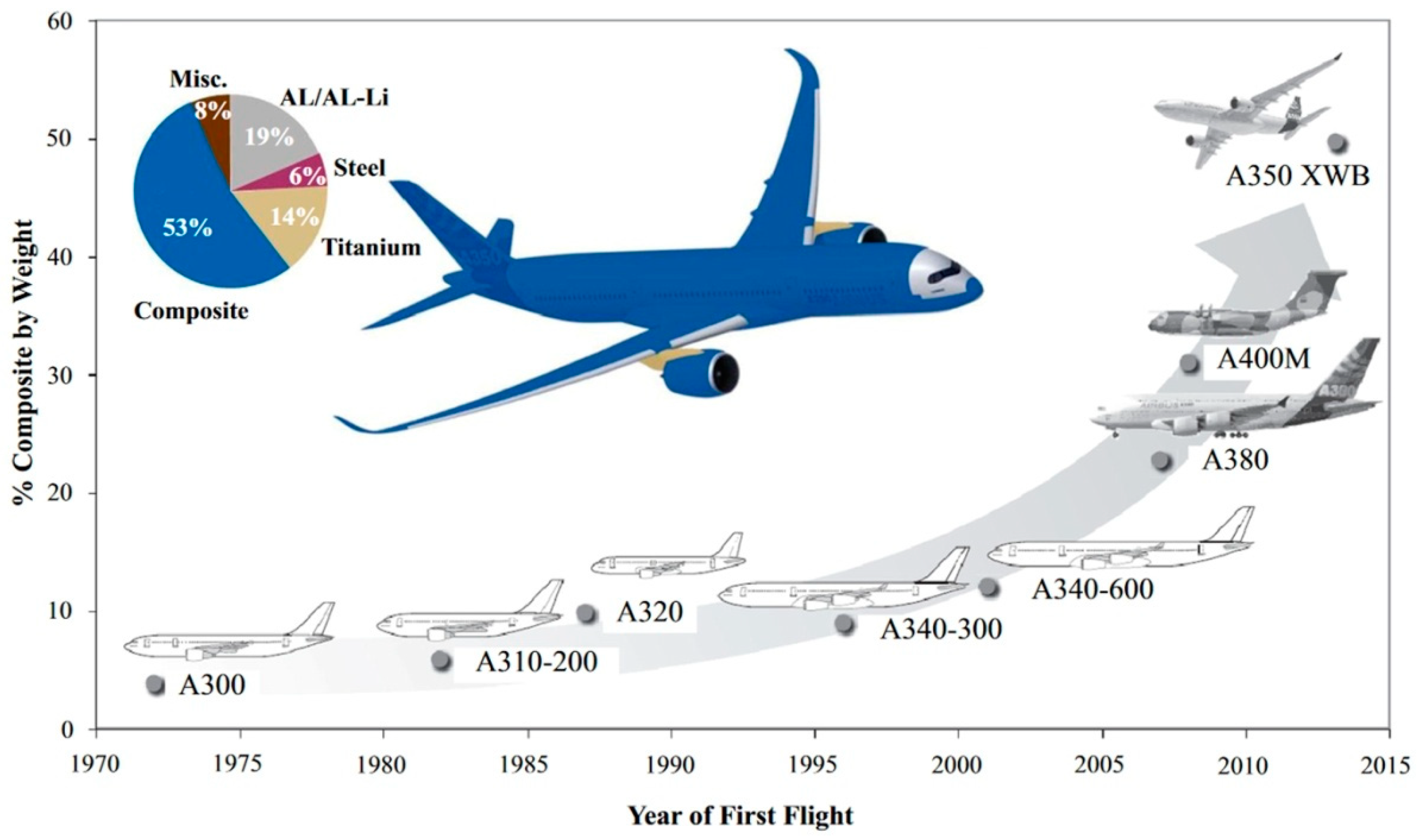

Composite Awareness Composite is a very sensitive material and technicians should have the knowledge to prevent damage and ex-pensive repairs. Cutting and forming thin sheets of metal usually performed as cold working Sheet metal 04 164 to 6 mm 14in thick Plate stock 6 mm thick Advantage - High strength good dimensional accuracy good surface finish economical mass production low cost. The classes scheduled for 2021 so far are.

This makes low carbon steel a more cost-eective. Various factors such as the metallic properties of the metal must always be taken into account. Aircraft Sheet Metal Practices Blueprint Reading Sheet Metal Forming and Heat Treating.

Aircraft Structural Assembly I. Aircraft Systems Training Course Details. Production Drawings Detail Assembly.

Upon completion of training the student will be able to assist experienced structures technicians in the aircraft line or base maintenance environment. Get ready to bend metal and make noise. Shapes are obtained by bending the sheet metal into the desired form and by joining components together using soldering brazing welding riveting or bonding.

PUB DATE Feb 74 NOTE 17p. BLOCK III - SAFETY PRACTICES IN SHEET METAL SHOP The student must be able to. Sheet Metal Work 2.

Define terms used in aircraft drawings. Learning by Doing The participant receives an work order to perform maintenance repair andor modification and assesses the work situation and the work order. This also means that tolerances in the title block of a drawing may be unnecessarily restrictive for certain dimensions and angles while very appropriate for others.

Aircraft Sheet Metal Repair I.

New To Sheet Metal Looking For Feedback About Dimensioning Autodesk Community Inventor

New To Sheet Metal Looking For Feedback About Dimensioning Autodesk Community Inventor

Solidworks Sheet Metal Gusset How To Add Strength To Sheet Metal Bends Youtube

How To Present The Mbd Data Of Sheet Metal Parts Engineers Rule

Solidworks Sheet Metal A Beginner S Tutorial All3dp

Nx 11 Advanced Sheet Metal For Automotive And Aerospace Parts Nx Design

Hudson 3 Technical Drawing Sheet Metal Drawing Drawing Sheet

Solidworks Sheet Metal A Beginner S Tutorial All3dp

J Compos Sci Free Full Text New Advances And Future Possibilities In Forming Technology Of Hybrid Metal Polymer Composites Used In Aerospace Applications Html

0 Response to "aircraft sheet metal drawing course"

Post a Comment